Micropiles

Micropiles today have found particular use in the field of construction because given their limited footprint and special technologies, they offer rational and economical solutions to soil engineering problems. Micropiles find wide scope of implementation especially in the sub-foundations of existing buildings, or in construction in space-constrained environments, or even in the consolidation of soils or structures that are no longer structurally reliable.

A micropile is a drilled pile with a returned diameter of less than 300 mm, the shaft of which consists of cast-in-place mortar or cement mixture and reinforcement usually consisting of a metal pipe or profile. It can be subjected to compressive, tensile and shear stresses, and can be vertical, horizontal or inclined.

Depending on the mode of injection, micropiles are distinguished into:

- Gravity micropiles: Casting of mortar at atmospheric pressure;

- Low-pressure micropiles: low-pressure mortar casting;

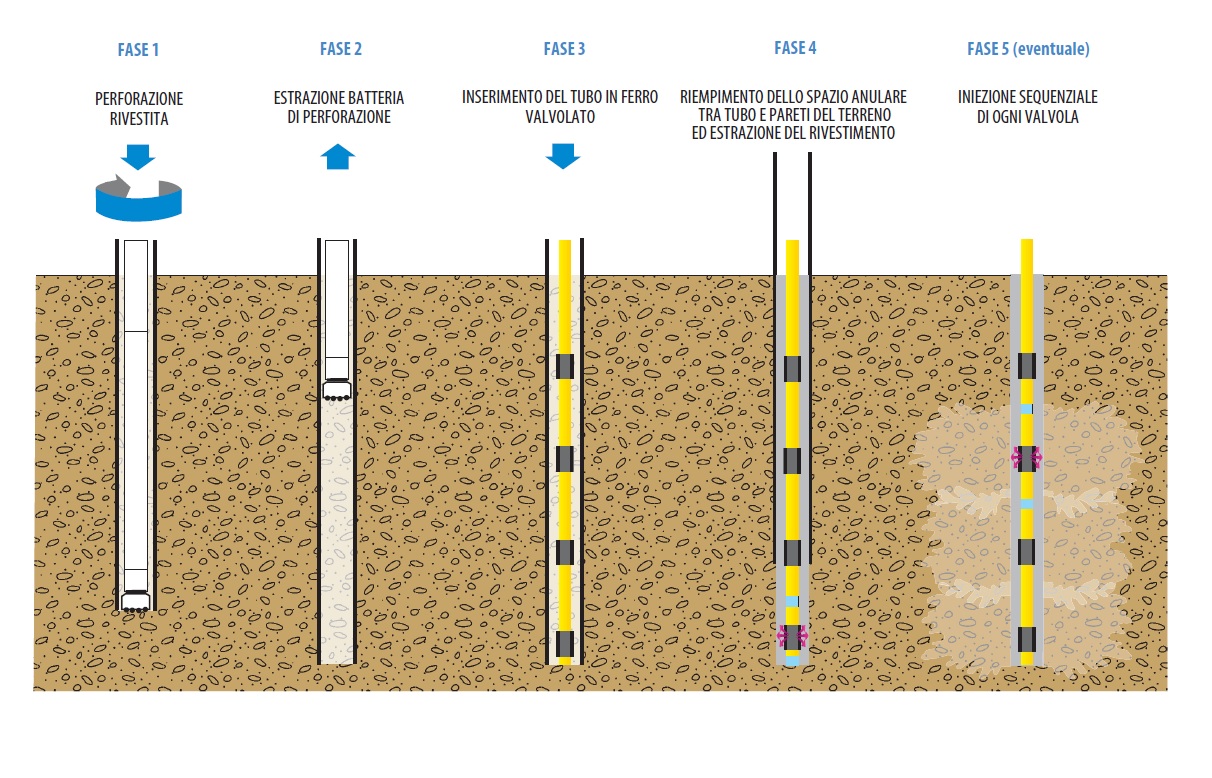

- High-pressure micropiles: Laying of valved metal pipe and injection of cement mixtures for sheath formation (primary injection) and subsequent injection of cement mixture through the valved pipe (secondary injection with controlled pressure and cross section).

The materials and construction elements are:

Metal armor – which in turn can consist of:

- Tubular metal reinforcement in Fe 430 or 510 steel with diameters ranging from 48 mm up to 250 mm with thicknesses ranging from 4 to 20 mm. Depending on the type of reinforcement, single bars or sections joined by means of threaded or welded sleeves or by means of male-female threads cut into the thickness of the tube can be adopted. In the case of valved pipes, the valves generally consist of 3-mm-thick rubber sleeves with metal rings welded to the pipe.

- Metal profiles: generally consist of single elements or jointed by appropriate welding.

Cementitious mortar and mixtures – in the case of cementitious mortar casting (gravity or low-pressure micropiles), the characteristics are: Cement Type: 325-425, Water/Cement A/V Ratio (depending on soil characteristics): 0.5 – 0.6; Minimum Strength: R’ck=25 MPa; Inert: Washed Sand

The modes of execution are:

- drilling: by rotopercussion or rotation with diameters ranging from 80 to 300 mm dry, with circulation of water, stabilizing mud or cement, with or without laying temporary liners depending on the stability of the hole walls. Tools used are continuous helixes the bottom-hole hammer or chisels with trilama, tricone or widia peaks. Borehole purging is achieved by the use of compressed air or by the same drilling fluids or by mechanical transport in the case of continuous helixes;

- Laying reinforcement, with the above characteristics;

- Casting with the above methods, distinguishing between gravity, low-pressure and high-pressure micropiles. In the case of high-pressure micropiles, sheath formation is first carried out with low-pressure injection of the cement mixture into the annular space between the reinforcing tube and the walls of the hole (primary injection); then secondary injection is carried out after 12 to 24 hours through the valves with appropriate expansion plugs (packers) introduced into the tubular reinforcement starting from the deepest valve