Continuous propeller shafts (CFA)

The C.F.A. (Continuous Flight Auger) pile is a drilled pile with a continuous helix cast in place with pressed concrete. The main feature of the system is the absence of bentonite sludge, polymer or pipe form lining, as well as the drastic reduction in the amount of soil extracted.

In the C.F.A. pile, a concrete of fluid consistency is normally used, possibly with additives to achieve the appropriate workability. It is executed in soils of any nature, of low or medium strength, indifferently in the presence or absence of groundwater.

It can also be carried out in unstable soils without the use of casing pipes since the method does not involve any “open excavation” situation.

The only limitation to the inconsistency of the soil is the ability of the soil itself to resist the pressure of the flowing concrete present at the end of the pour, like all types of piles cast in place without a permanent coating.

The method makes it possible to make drilled piles having safety and load-bearing characteristics and at a time to minimize both noise and vibration. The C.F.A. pile is therefore the pile system with the least disturbance:

- For the soil, in fact unlike other types of bored piles, it is normally not removed during the drilling stage, but even compressed for the introduction of the auger. During the pouring phase, it is pressed by the concrete.

- For existing neighboring buildings The auger penetrates the ground gradually without causing any vibration and noise so that C.F.A. poles can be used even in built-up areas and adjacent to structures.

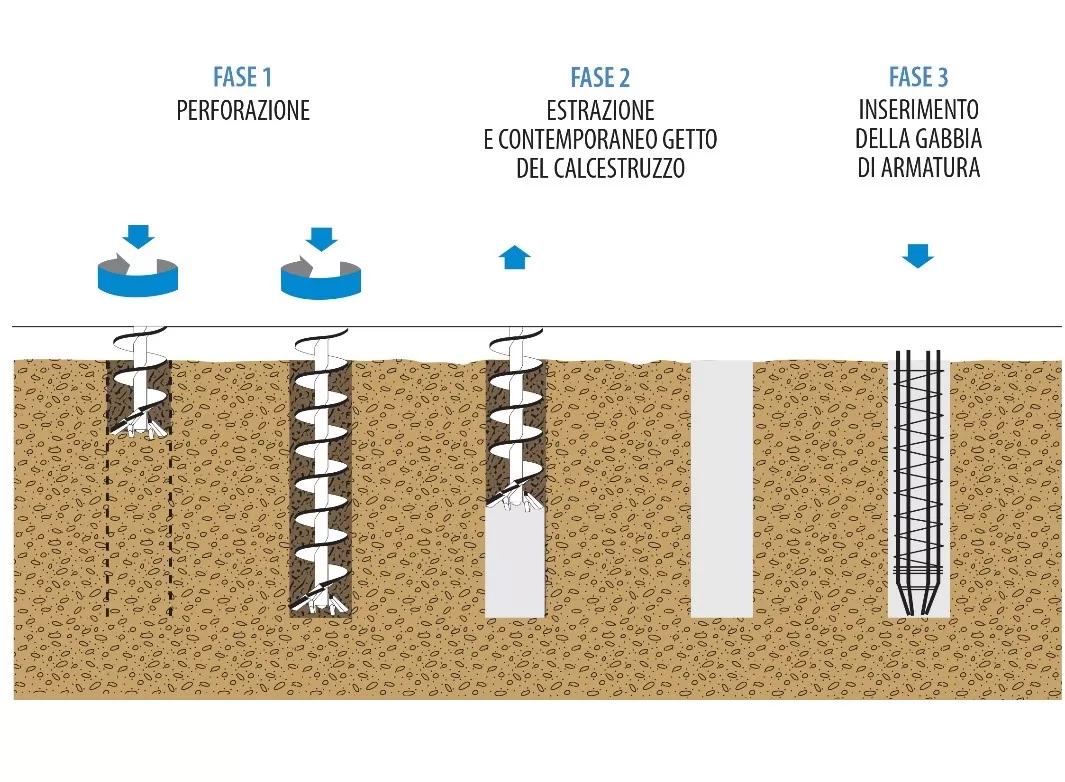

The equipment used consists of: a drilling tool, consisting of a continuous propeller or auger, connected at the top to a rotating head sliding along a tower-driver, penetrates the soil by its tendency to screw and brings a modest amount of soil to the surface. The auger rod, during drilling, is closed at the lower end. Thus, some lateral compression takes place, which increases the original natural density of the soil. Speed of rotation and penetration can be varied according to the characteristics of the soil. The height of the water table does not affect planning operations in any way.

The materials used are:

- CASTING OF CONCRETE: Once the design elevation is reached, the pile is cast. Concrete is fed through the auger shaft and exits under pressure at the base of the auger. Gradually, as the shaft is formed, the auger is pulled out of the ground. The concrete pressure exerts a continuous upward thrust on the auger, cooperating with the extraction while ensuring absolute continuity of the pile shaft. Pouring proceeds until the pile is complete by gradually pulling out the auger as the concrete flows with continuity.

- REINFORCEMENT: The reinforcement of the C.F.A. pile is placed in place after completion of casting for the full length required by flexural stresses. in the case of long piles subject to tensile stresses, special forms of reinforcement may be placed in place to affect the full length of the pile.